SYSTEM SUPPLIER

HEUSCHKEL is an aluminium and zinc die casting foundry with integrated finishing and has the competence to reliably control even complex value chains with many parties involved.

This allows our customers not only to award individual products to us, but to outsource entire process chains of complex assembly groups. We control these processes independently and deliver the desired quantity of finished, assembled and quality-controlled articles directly to your belt.

We are your competent partner for joint development of your idea into a castable serial product with exactly those properties that are required for the intended use. We advise you in the choice of material, casting design and casting method. We test the design’s properties in simulations. Then we can provide you with the final product as a display model in 3D print or produce a mini-series in prototyping.

DEVELOPMENT

PRODUCT ADVICE

Your draft stands at the beginning. We support you with it by feasibility studies, optimisation and value analyses with regard to the material, casting design and casting method according to FMEA systematics.

DEVELOPMENT

In order to shorten your development time and to keep modification costs after the design phase as low as possible, we offer co-design, FEM analysis as well as mould filling and solidification simulation within the scope of simultaneous engineering.

PROTOTYPING, PILOT RUNS

We deliver first display models in plastic 3D printing process or as milled parts from solid material. If you require near-series properties or wish a pilot run or mini-series, core casting parts with relatively filigree contouring and low model costs are the first choice.

CASTING ALLOYS

With the choice of the proper alloy, you define the properties of your serial product. Properties and casting characteristics have an influence on the product design. At HEUSCHKEL, you find standard and special alloys in aluminium and zinc. We advise you in the selection of the suitable alloy for your product.

TOOLMAKING

Moulds, punching tools, jigs and fixtures as well as core models are designed, constructed using 3D systems and optimised through simulations internally. The realisation is implemented in our internal mould and toolmaking unit, through specialised partners or via our established network of Asian suppliers.

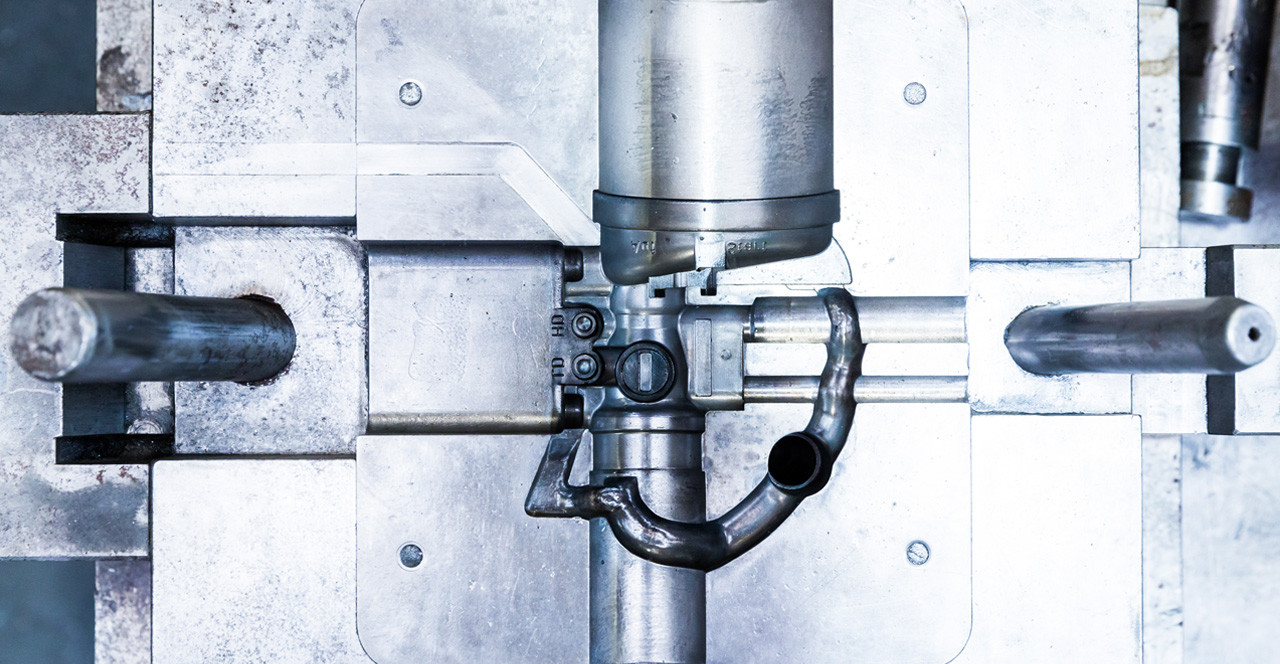

DIE CASTING

ALUMINIUM DIE CASTING

Cold-chamber casting

Dosage of molten material in piston chamber, mould filling process in 3 phases:

1: Lead of shot plunger, molten material up to cut

2: Mould filling shot in the millisecond range

3: Static hold pressure for sealed feeding

LAMINAR DIE CASTING

— Economic alternative to chill and low-pressure casting at high numbers of pieces

— Controlled slow, low-turbulence (laminar) mould filling in phase 2 at wall thicknesses ≥ 4 mm

ZINC DIE CASTING

Hot-chamber casting

High productivity and tool service lives, in contrast to cold-chamber casting the shot plunger is integrated in the holding furnace. This method is unsuitable for aluminium due to the higher process temperatures and the chemical affinity Al-Fe. Blank finish: punching, blasting, smoothing

CORE CASTING

The basis of core casting is silica sand with a defined grain size under the admixture of resin binder. The dry sand is compacted in the core shooter and hardened chemically by gassing (CO₂ resp. cold box process). This method is suitable for the development of prototypes, pilot run casting and mini-series due to low core box costs and short production times.

COMPLETION

MACHINING

Machining is carried out using CAM/CNC technologies, with vertical and horizontal machining centres to 5-axis technology.

SURFACE FINISHING

We offer among other things:

_Smoothing, blasting

_Anodic oxidation (anodising, hard-coating)

_Cathodic dip painting (KTL method)

_Powder coating

_Wet painting

_Chromate coating

_Zinc coating

COMPONENT ASSEMBLY

The completion of machined and finished cast parts with external components up to the assembled component ready for installation completes our system offering. Of course, our experts even take over full control of complex value chains as well.